Building Cold Room - Cold Room – Xinneng

Building Cold Room - Cold Room – Xinneng Detail:

Product Introduction

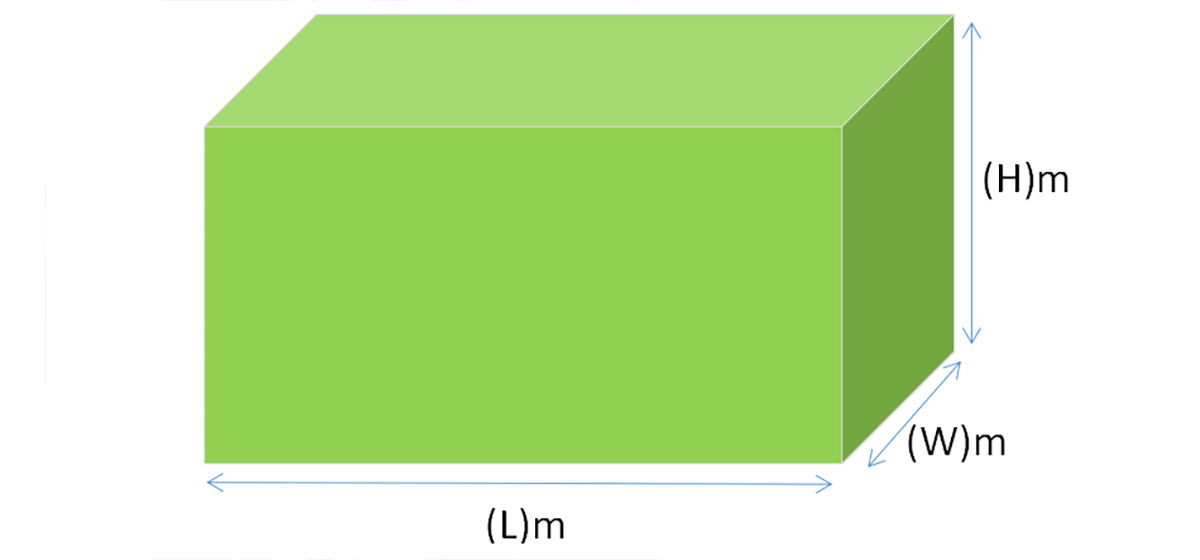

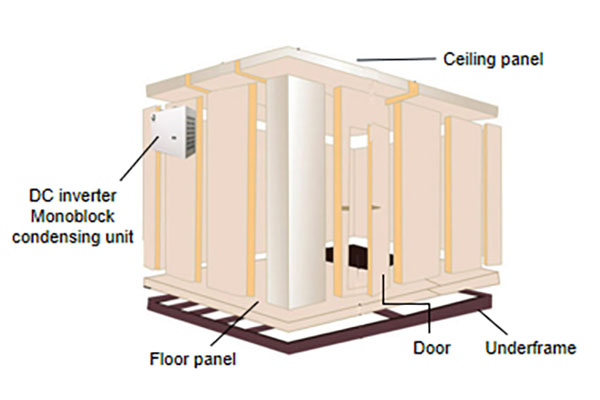

The cold room is provided by the customer with the required length, width, height and use temperature. We will recommend the corresponding cold room panel thickness according to the use temperature. High and medium temperature cold room generally use 10 cm thick panels, and low temperature storage and freezing storage generally use 12 cm or 15 cm thick panels. The thickness of the steel plate of the manufacturer is generally above 0.4MM, and the foaming density of the cold room panel is 38KG~40KG/cubic meter per cubic meter according to the national standard. The factory will make doors of different sizes according to customer needs, usually the size of the standard door is 0.8m*1.8m. If the customer does not have the desired size, we will also have standard cold room sizes for customers to choose.

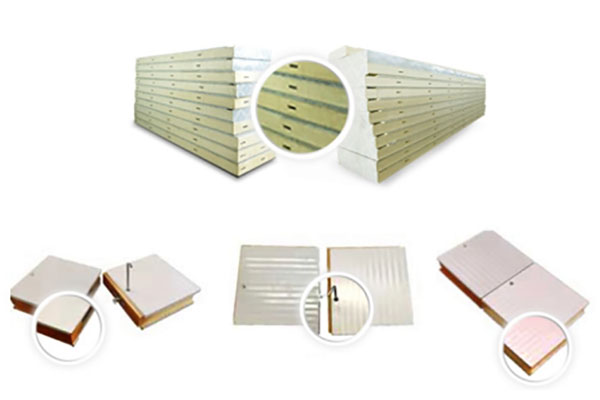

The polyurethane cold room panel uses lightweight polyurethane as the inner material of the cold room panel. The advantage of polyurethane is that the heat insulation performance is very good.The exterior of the polyurethane cold room panel is made of SII, PVC color steel plate and stainless steel plate components.The advantage of this is to prevent the temperature spread of the cold room panel due to the large temperature difference between the inside and the outside, thereby making the cold room more energy-saving and improving the working efficiency of the cold room.

Features of Polyurethane Cold Room Panel

1. Rigid polyurethane has low thermal conductivity and good thermal performance.

2. Rigid polyurethane is moisture-proof and waterproof.

3. Rigid polyurethane fire, flame retardant, high temperature resistance.

4. Due to the excellent thermal insulation performance of polyurethane panels, it can reduce the thickness of the building envelope and increase the indoor.

5. Strong resistance to deformation, not easy to crack, stable and safe finish.

6. Polyurethane material has a stable porosity structure and is basically a closed-cell structure, which not only has excellent thermal insulation performance, but also has good freeze-thaw resistance and sound absorption..

7. High comprehensive cost performance

The thickness specifications of our polyurethane cold room panel are: 75.100.120.150.180, 200MM for selection. The main protective materials are: embossed aluminum plate, stainless steel plate, color zinc steel plate, salted steel plate, and standard floor plate. We usually use embossed aluminum plate and stainless steel plate.

To customers choose

Freezer Room Project Information:

| Length | Width | Height | CBM | Temperature | Quantity |

Product Details

|

Thickness of panel |

50/75/100/120/150/200mm |

|

Panel steel cover |

Color steel,Stainless steel,Galvanized(customized) |

|

Thickness of panel steel cover |

0.326/0.4/0.426/0.476/0.5mm |

|

Density |

40±2kg/m3 |

|

Width |

960mm |

|

Type |

Insulation pu sandwich panel with cam-lock |

|

Color |

White |

|

K VALUE |

≤0.024W/mK |

More Pictures

Product detail pictures:

Related Product Guide:

Our advancement depends over the superior machines, exceptional talents and continually strengthened technology forces for Building Cold Room - Cold Room – Xinneng , The product will supply to all over the world, such as: Mauritius, Singapore, Honduras, With strong technical strength and advanced production equipment, and SMS people purposefully , professional, dedicated spirit of enterprise. Enterprises took the lead through the ISO 9001:2008 international quality management system certification, CE certification EU ; CCC.SGS.CQC other related product certification. We look forward to reactivating our company connection.

High production efficiency and good product quality, fast delivery and completed after-sale protection, a right choice, a best choice.